Another hallmark of MBUSI’s new workspace is a flexibility to accommodate a variety of present and future uses. That desire for flexibility drove the development of the myriad of seating and meeting options. Providing a menu of workspace options gives team members the ability to choose where they work based on team size, activity type, or personal (or generational) preference. Power is integrated into much of the furniture to further facilitate the ability to work from anywhere. Even dining and break rooms have been outfitted to become “work cafes”. Some of the conference rooms were furnished to allow stand-up meetings around a workspace. But the flexibility of the space is not limited to the range here-and-now uses, but also has the ability to reconfigure to meets needs that MBUSI and the design team don’t even see coming yet. Not only is the furniture moveable, but even the VIA and Post & Beam systems are demountable so that the entire space can adapt with the growing and changing needs of MBUSI. That kind of flexibility extends from floor to ceiling. The Shaw Contract carpet tiles - whose colors, shape, and textures help define space for gathering and circulation - can easily be picked up and moved due to the lock-dot application method. An Armstrong cloud system was used to create a planar organizational element through the space overhead without the permanence of an architectural soffit. Every consideration was given to accommodating the needs of MBUSI’s team - both now and in years to come. We want to thank the team of suppliers, product representatives, and contractors that contributed to the success of this project. The result is a truly innovative and dynamic workspace.

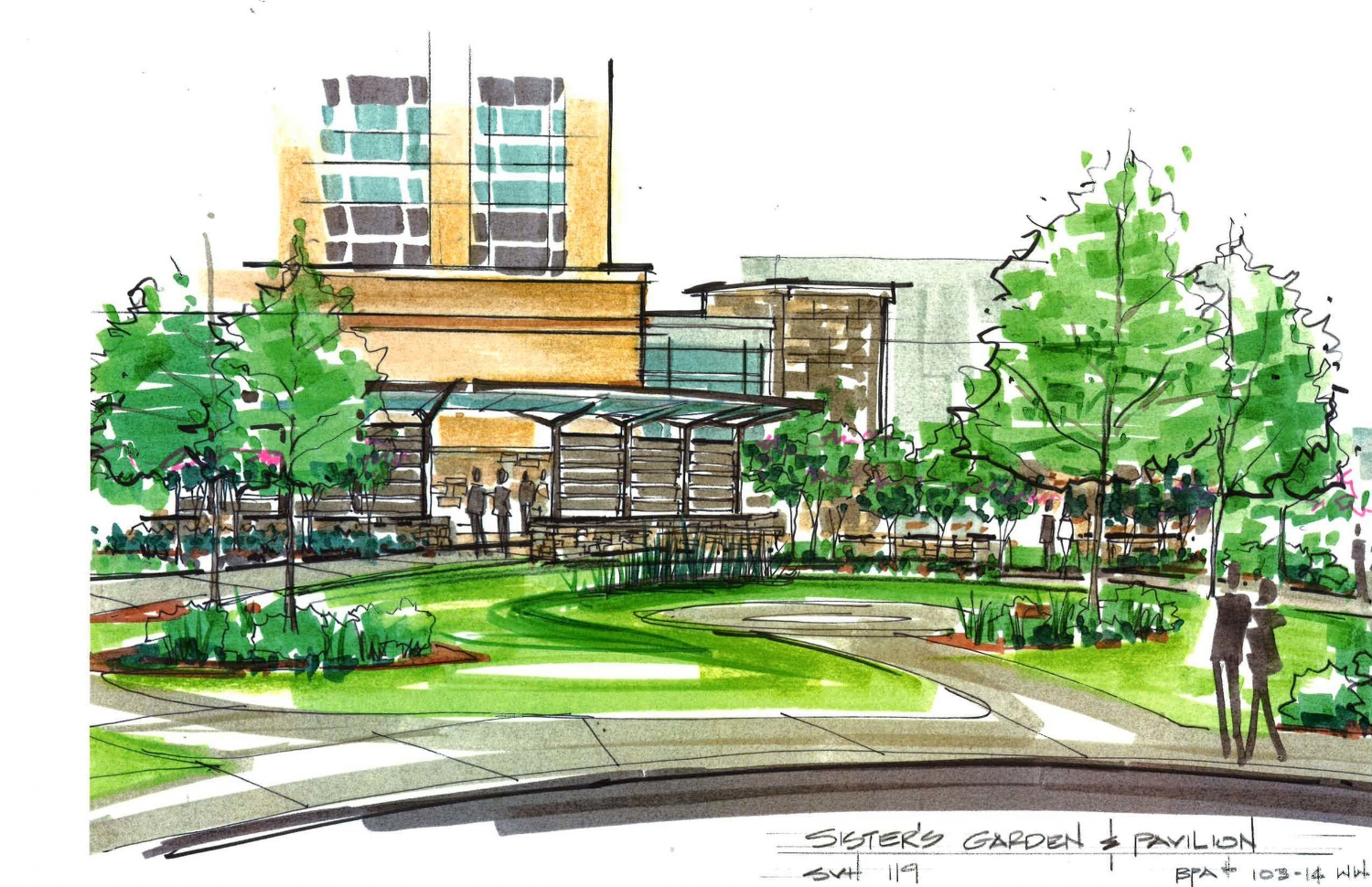

RENDERING VS. REALITY

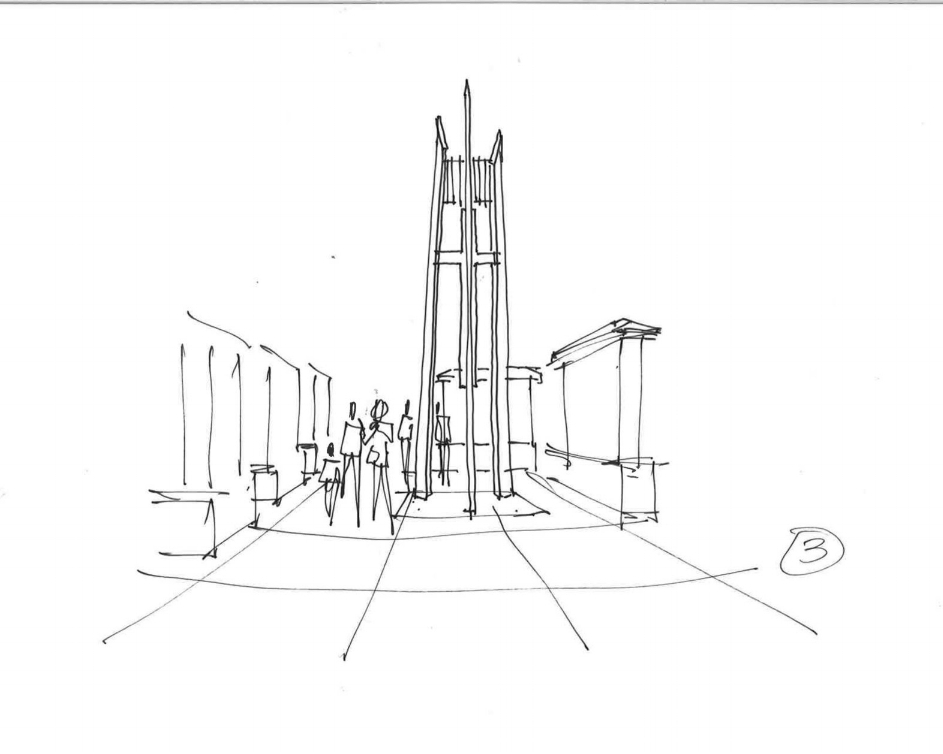

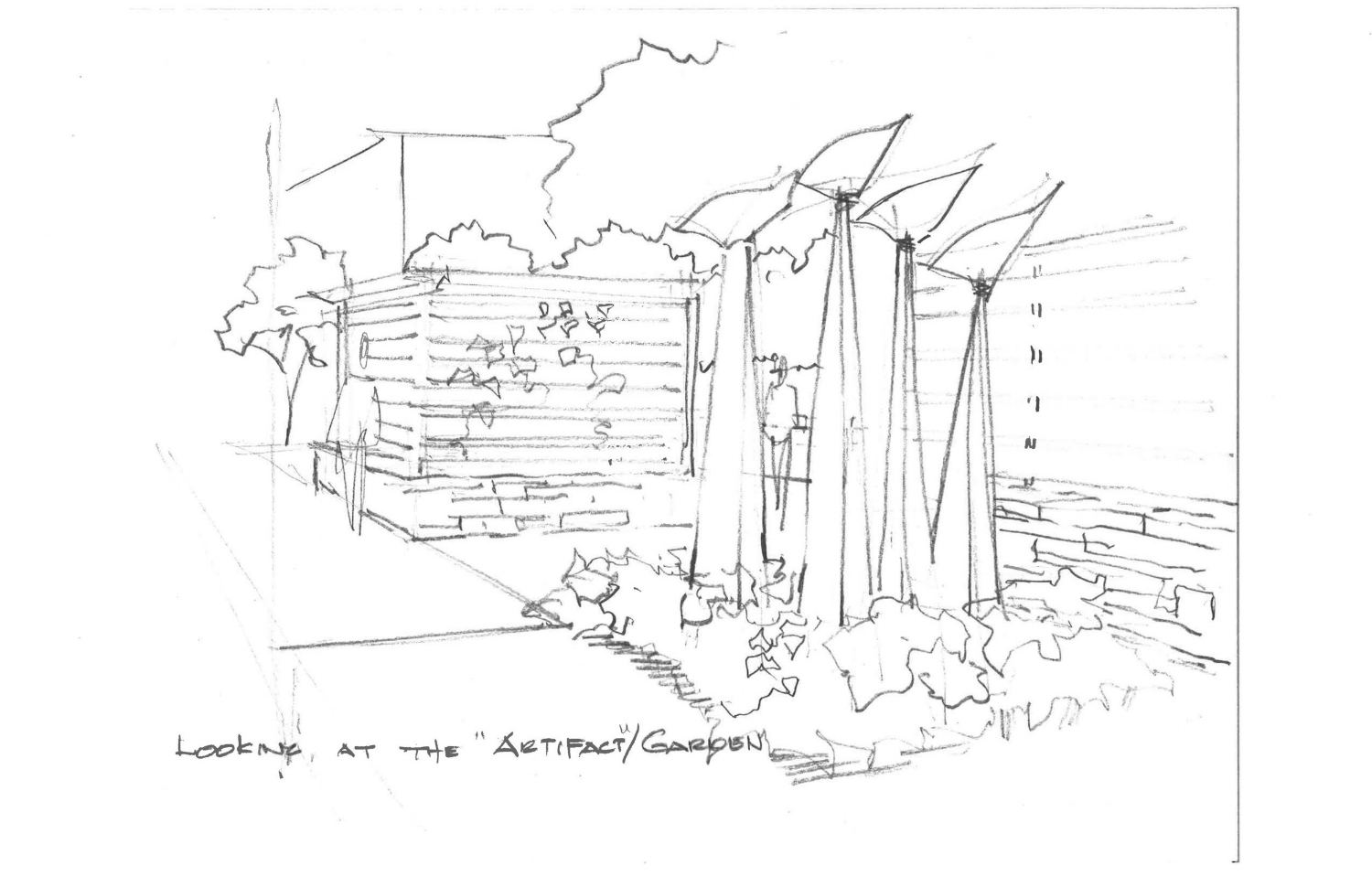

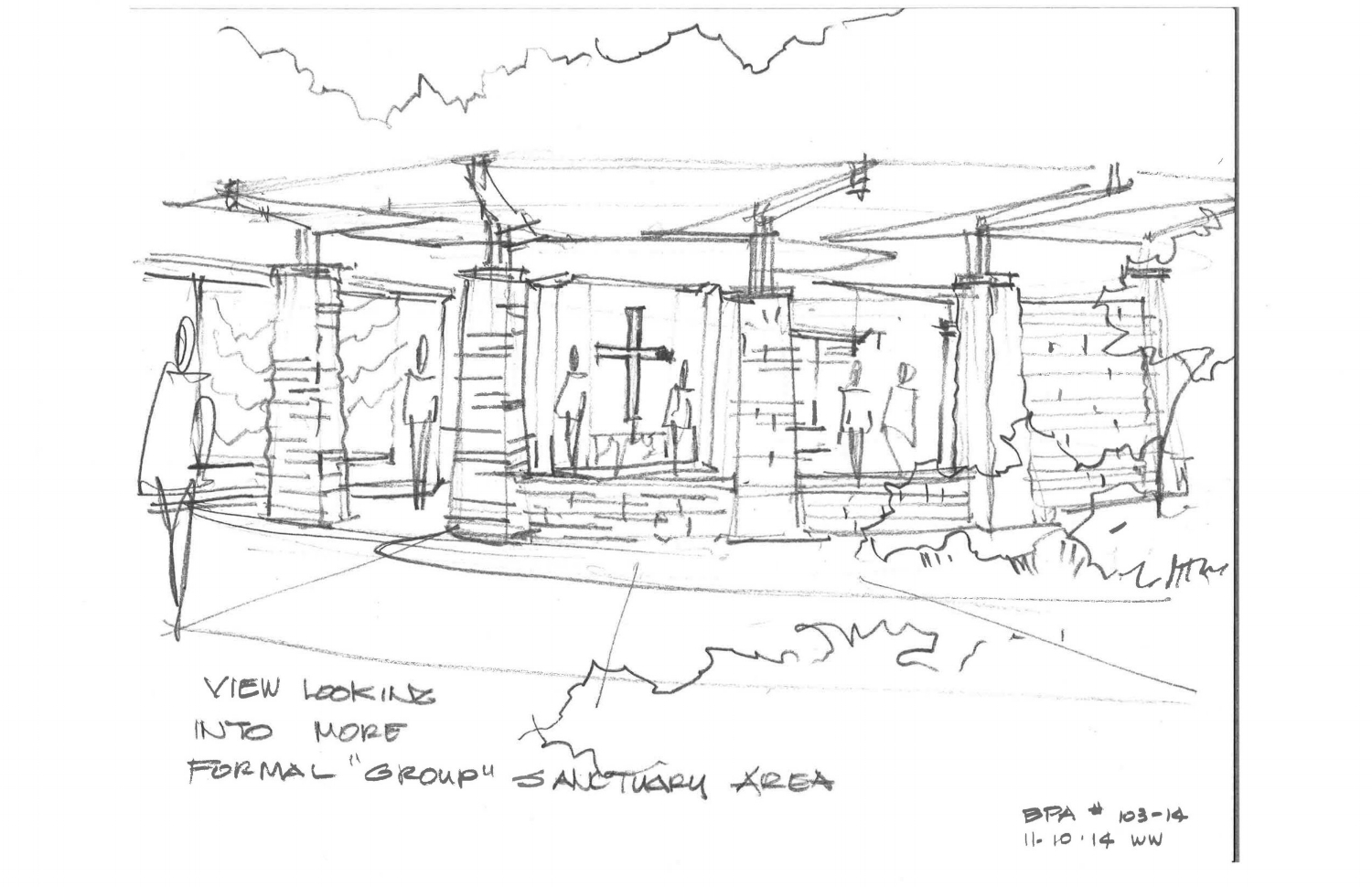

The involvement of innovation in this project was not limited to the products used to shape the final outcome. It also included the process by which those concepts and products were brought to bear. A project of this size and scope is inevitably going to engage a variety of needs and preferences across the many departments represented. As a design team, we found it valuable to realistically represent the proposed outcome of each space so that each user group could provide real-time feedback during the design phase. To do this, we relied on a core functionality of the design tools we use on projects of all sizes. We were able to build a digital 3D model of each space that served as a basis for a series of photo-realistic renderings that provided a hyper-accurate visualization of the final product in the middle of the design process. This effort was bolstered by working with suppliers that not only provide accurate models of their furniture and systems, but also life-like representations of the material choices for each piece. Take a look at the images below for a side-by-side comparison of the rendering vs. reality. Can you tell which one is which?